Speed-of-use and Accuracy

Previous solutions to inspecting sheave wheels make use of contact techniques. This includes the use of pantographs, sheave gauges, and even the use of plaster casts. None of these methods allow the user to effectively quantify readings or easily record or transmit readings.

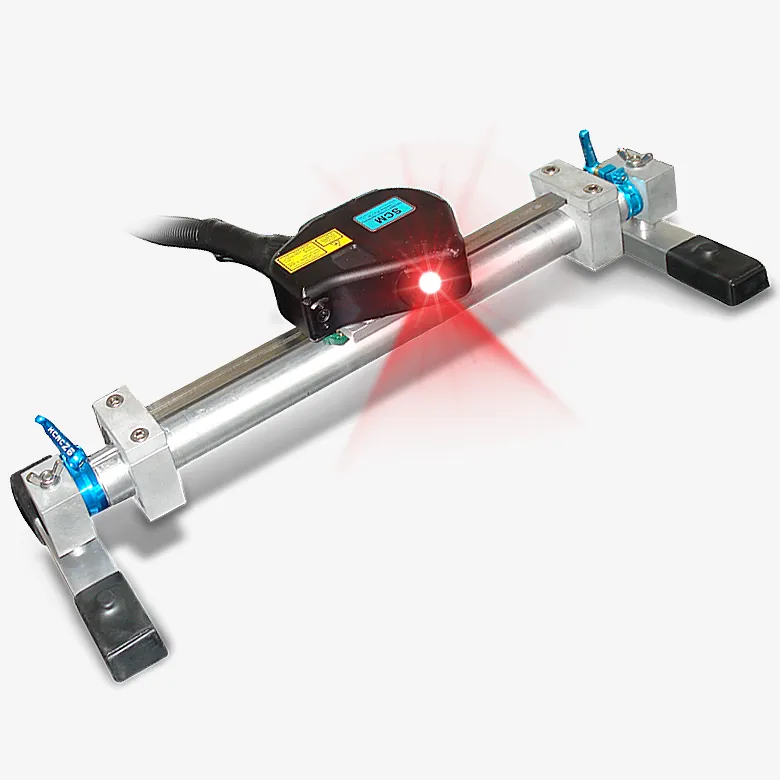

The speed of use and accuracy of the sheave wheel profiler can be attributed to its non-contact method of measurement. Even a novice user can perform a scan within two minutes and achieve accuracies of better than 1mm.

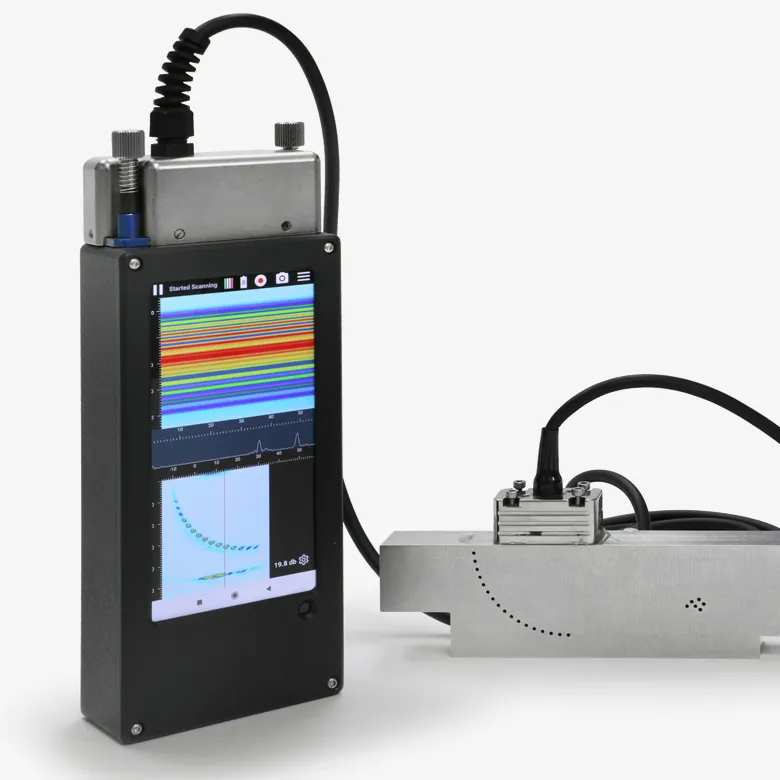

Software Package

The included software allows the user to scan a sheave wheel with a single sweep of the laser. The software allows for an easy comparison with previous scans and trending of profiles for determining wear rates. It also provides a set of measuring cursors and manufacturer’s specifications for automated report writing.