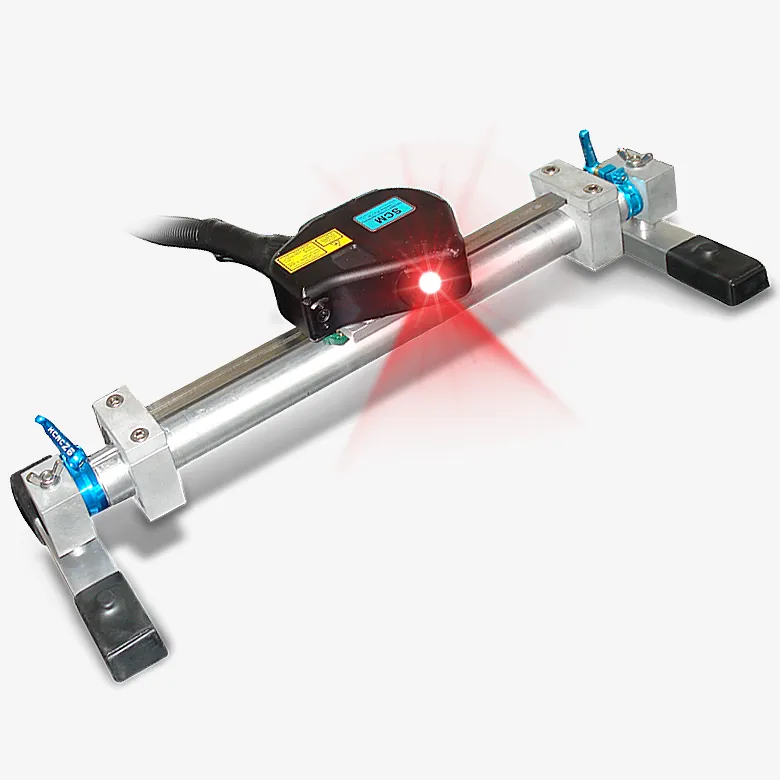

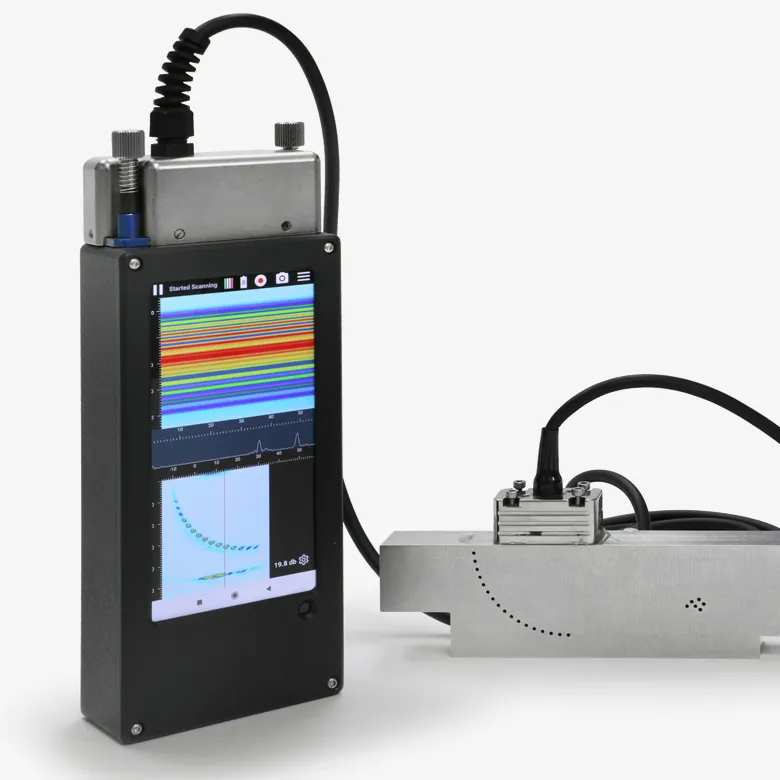

Achieve precision and confidence in your inspections with our advanced Non-Destructive Testing (NDT) Laser Profilers, designed specifically for high-accuracy profiling of gears, drum wheels, and other rotating or complex-shaped components. These non-contact systems use laser-based measurement to capture detailed surface geometry, helping you detect wear, deformation, misalignment, or manufacturing defects—without disassembly or downtime. Whether you're monitoring gear tooth wear in power transmission systems or evaluating the surface profile of heavy drum wheels in rail, mining, or industrial machinery, our laser profilers deliver consistent, high-resolution data for proactive maintenance and quality assurance.