Laser Gear Profiling

For all industrial systems that include the use of heavy-duty gears as part of the process, the eventual wear of the gears is an inevitable outcome. Due to the high cost of purchasing and installing such gears, the life cycle of the gears must be factored into the operating cost of the machine.

It should be noted that the replacement intervals on different gears vary significantly (even on similar machines) due to different operating conditions (e.g., lubrication used, loading, alignment and several other uncertain factors). It can thus not be estimated solely based on the intended conditions of operation.

Laser Gear Profiling

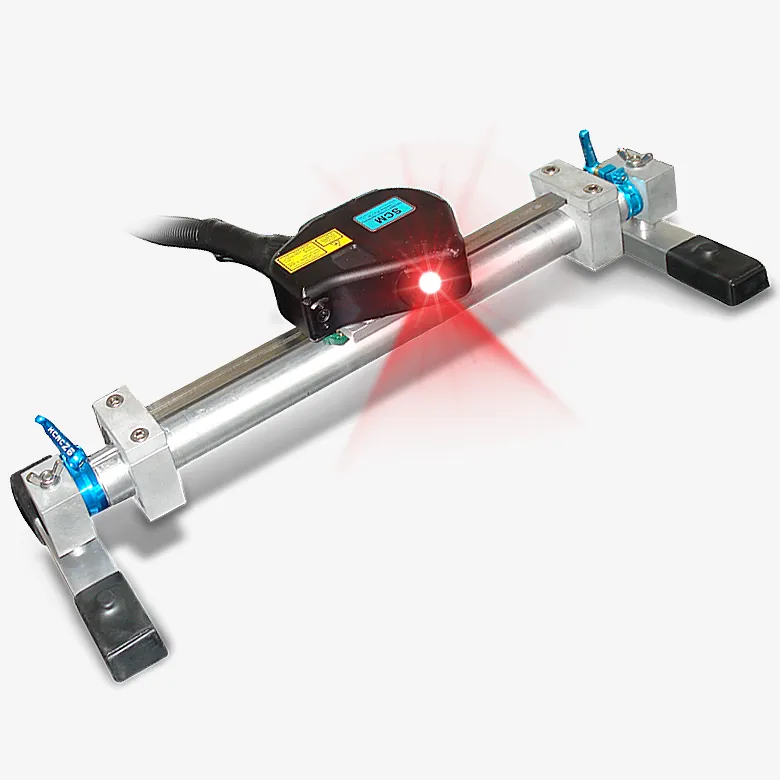

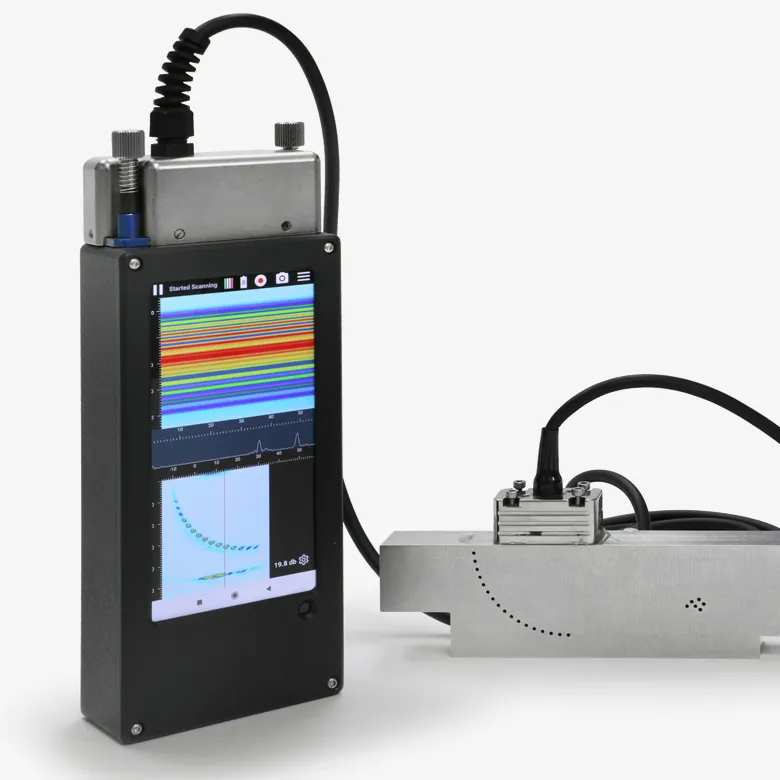

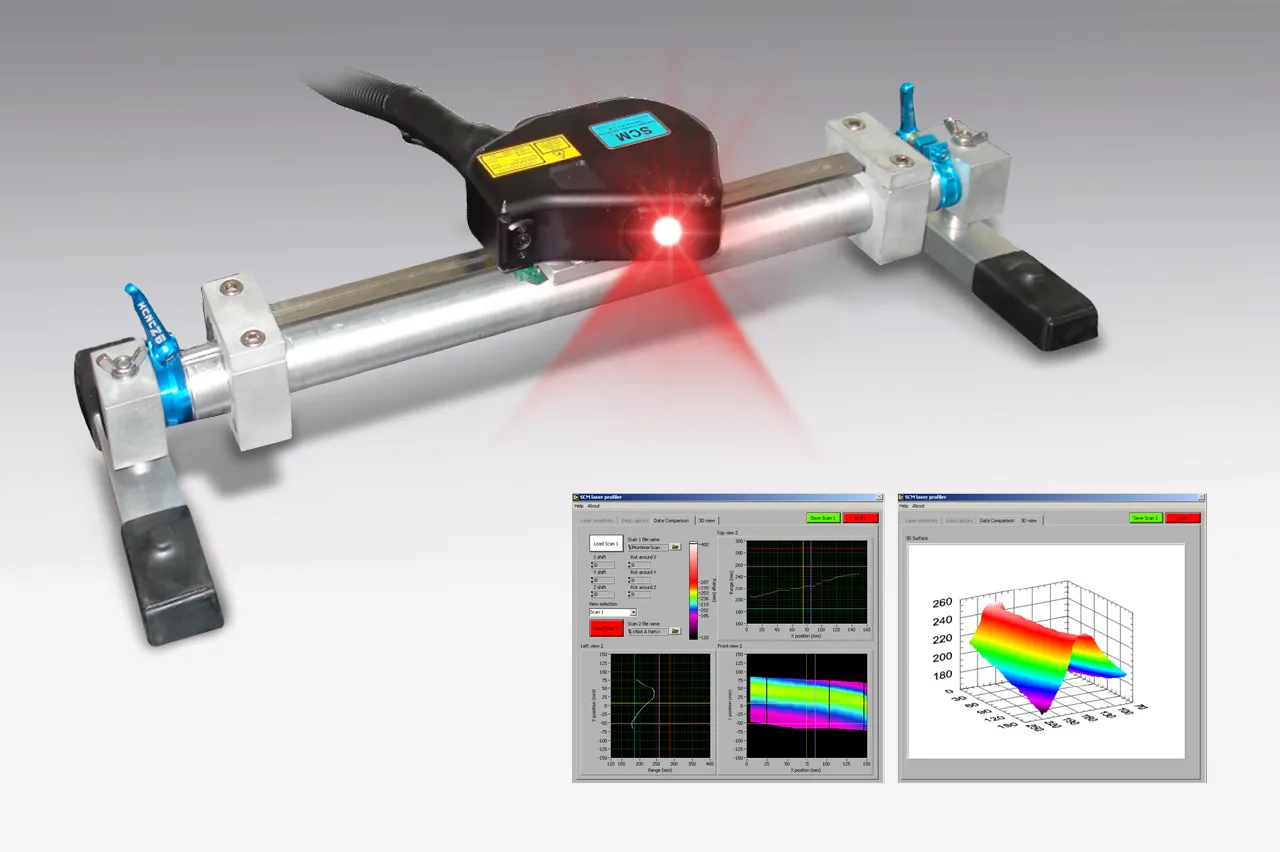

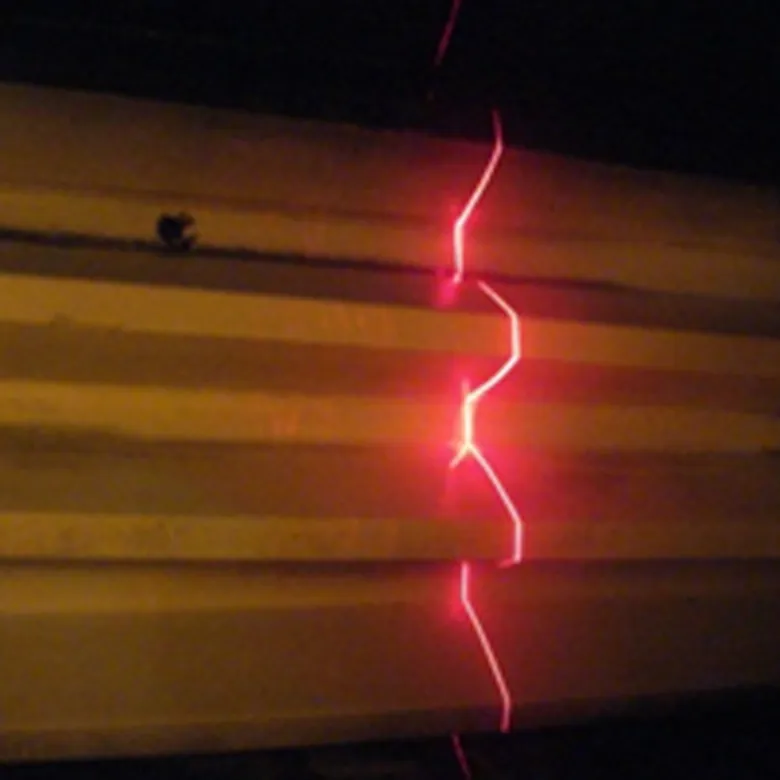

The speed and accuracy of the Scanbuddy 3D Laser Scanner may be attributed to the non-contact measurements that lie at the heart of the technique. A digital interface’s bonus is that it allows for easy scan comparison and trending of wear rates, as well as easily accessible data storage.