StringBuddy® Matrix

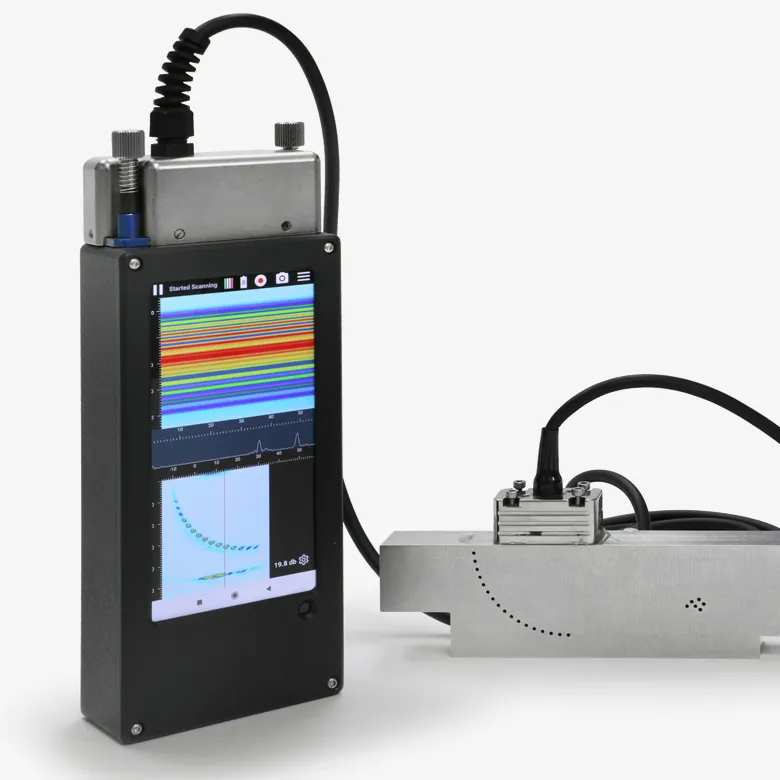

Smaller defects, not only need better inspection techniques, but also better representation of the captured data. Instead of statistical measurements, a complete scan of the component under inspection is required. This usually requires data to be captured at all positions, such that a 100% inspection is achieved.

From USD$3,910

Portable Inspection Solution

Inspections requiring such coverage, usually make use of expensive robots, crawlers or manipulators. In the case of site work or rope access work, such large equipment is costly, impractical and time consuming to setup. Instead of using mechanised systems, ScanBuddy now offer the StringBuddy® Matrix.

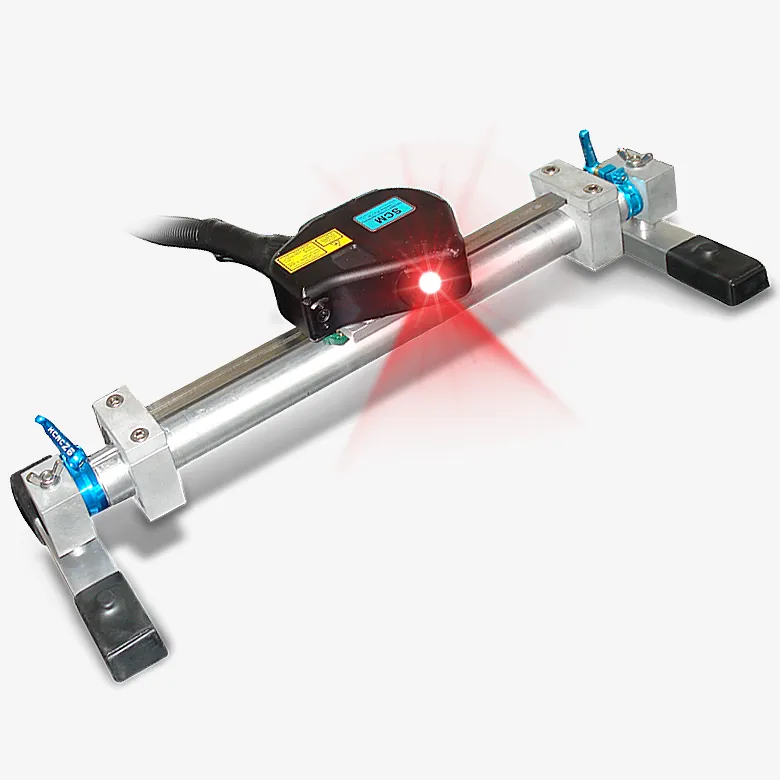

This encoder is very portable, consisting of a small control box and two wire encoders. The system is therefore easy to transport in hand luggage, and easy to manoeuvre during inspections.

Easy Operation

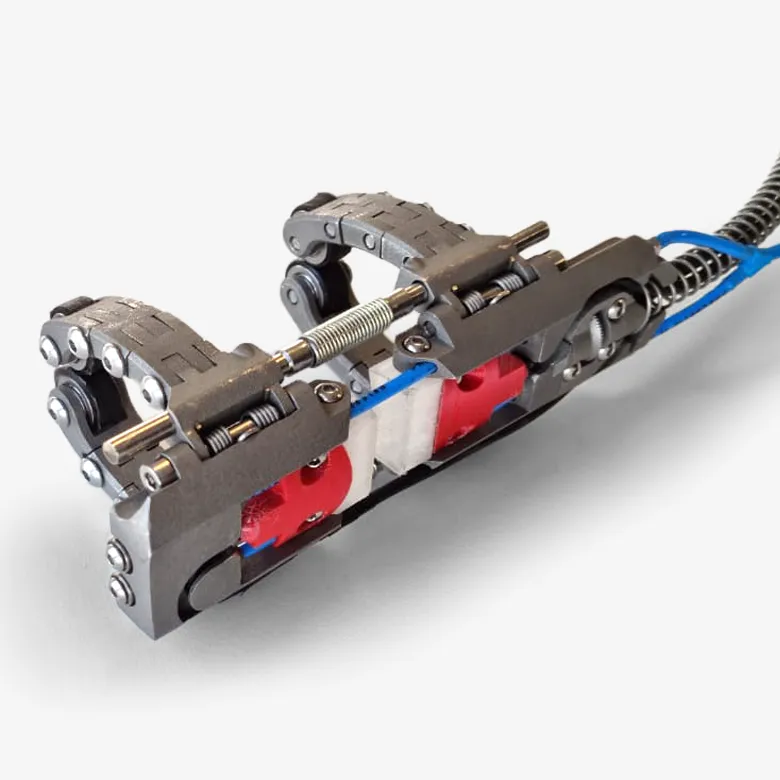

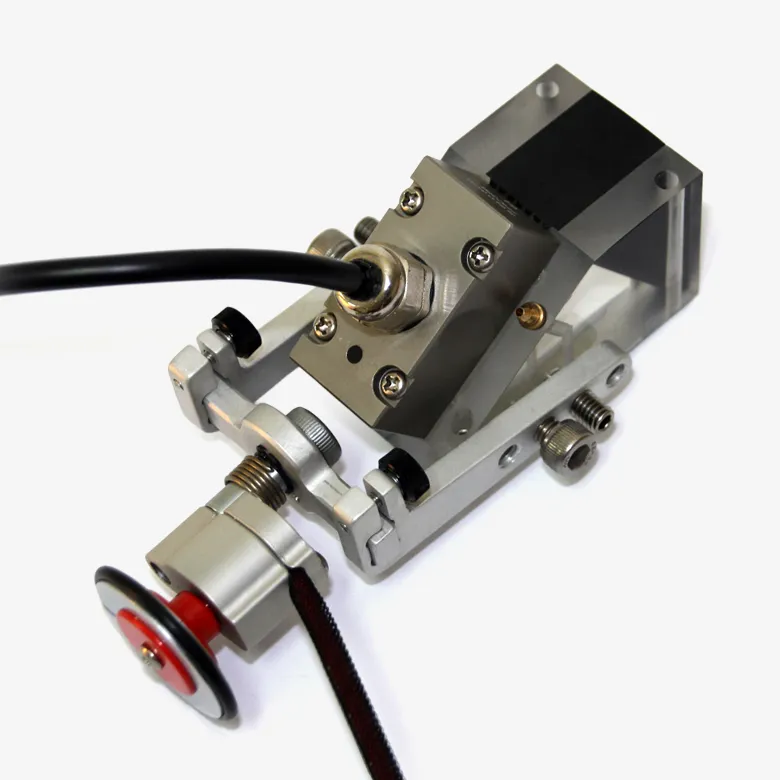

The small control box is connected to your existing NDT equipment, such as a phased array set, UT set, eddy current set, or any equipment that can be used with two or more encoders. The two encoders are then simply clamped onto the component under inspection, with the use of the two magnetic feet, or two suction cups (optional).

The probe used for the inspection is then connected to the end of both wire encoders and calibrated with the use of a push button on the control box. Once with the probe against the left encoder and once against the right encoder. The NDT equipment then receives the position feedback as if it were connected to two perpendicular encoders, thus simulating a robot, manipulator or crawler. Data captured as is normally done for C-Scan.